Blog / 15 posts found

EZ-One Tracksaw Woodworking Center

Adding a Tracksaw to your Woodworking Table saws scare me so I decided it was time to add a Tracksaw to my woodworking. I looked around for a bit and discovered the EZ-One Tracksaw Woodworking Center from Eurekazone. Initially the price of the unit was out of my reach so I began buying the equipment a little bit at a time. Once I had assembled enough parts I decided to build my own DIY EZ-One Tracksaw Woodworking Center. I got my first pieces of equipment used on Craigslist. I started with a piece of Track and some clamps. Later I […]

How to Square Up Stock in a CNC Milling Machine

How To Square Up Stock In the CNC work shop one of the first tasks a machinist must learn to do well is how to square up stock in a cnc milling machine. Squared up stock has all sides parallel to their opposite side and all angles perpendicular to adjacent sides. Using Square stock allows you to create parts that mate well together. It is impossible to repeatedly create parts without starting from squared up stock. Since one of the reasons we use CNC milling machines is to create multiples identical parts, it only makes […]

Making a CNC Milling Machine – Increasing the travel

Making a CNC Milling Machine – Increasing the travel Part 3 I have been working on making a CNC milling machine from a Grizzly G0704 manual milling machine. Welcome back to my blog. I have looked at several modifications to the Grizzly G0704 and one that seem really useful is increasing the travel on the Y and Z axis. Increasing the travel will require some pretty serious modifications to the existing castings and will definitely void your warranty. Increasing the travel of the Y axis will require that I

The Warp Drive Project Story – Mach3 Motor Tuning Video

Mach3 Motor Tuning Video The Warp Drive Project Story – Faster CNC Router Part 3 I just found an old video I planned to post to Youtube a few years ago when I was developing the Warp Drive Project. For some reason I never published the video then, but I decided to do so now. I was doing motor tuning to find out how fast I could make the Z axis go. Back in the early days this seemed fast. Since then I have increased the speed by a factor of 3. The original Warp Drive project parts were made […]

Making a CNC Milling Machine -Ballscrew mounts

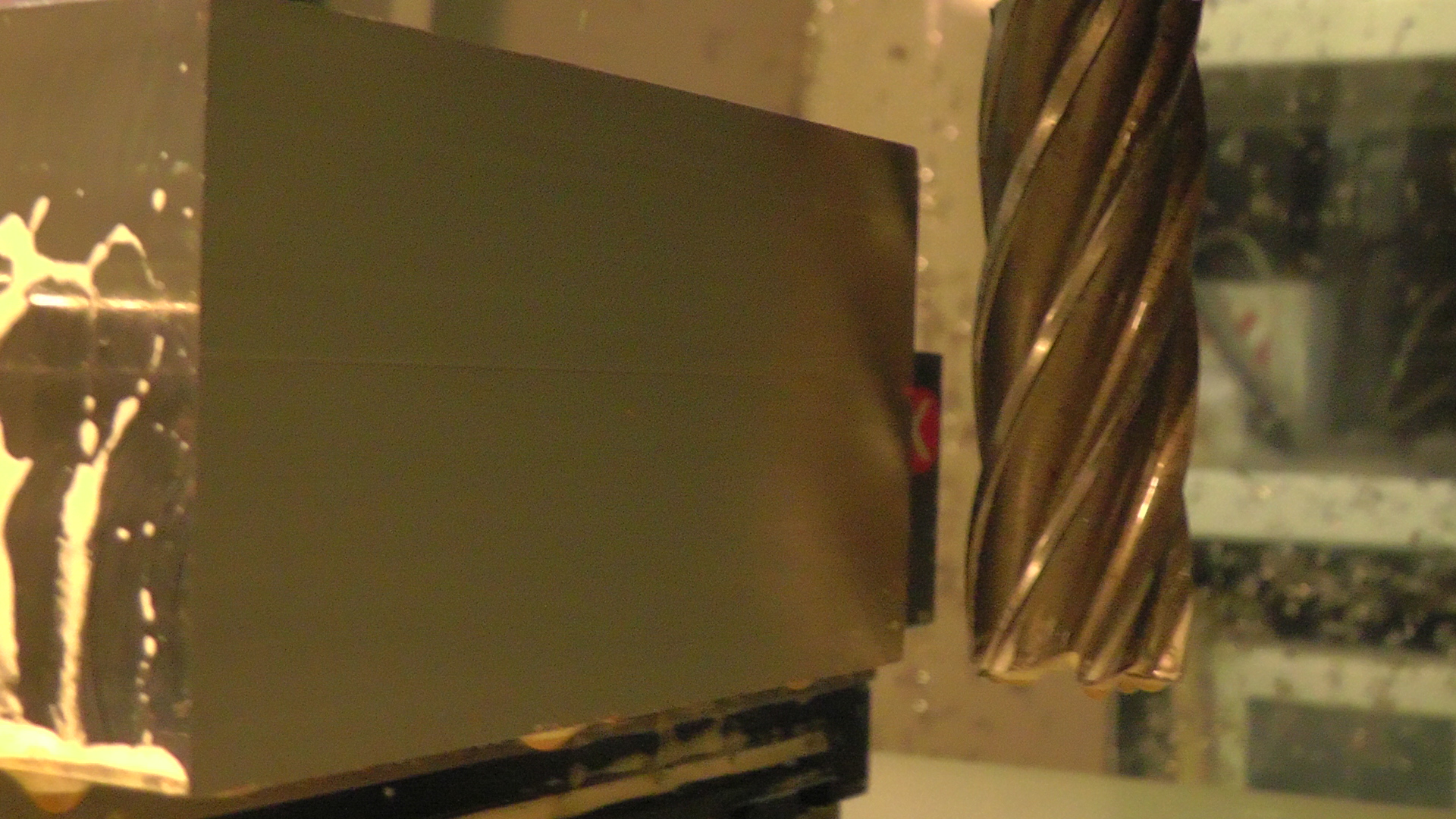

Making a CNC Milling Machine -Ballscrew mounts Converting a Grizzly G0704 milling machine to CNC – Part 2 Making a CNC Milling machine requires a lot of metal working. Most people will use a manual milling machine to do the metal work. I was lucky to have access to a CNC machining center so that is how I made my ballscrew mounts. A Ballscrew (sometimes spelled Ball Screw) is a type of linear actuator that translates rotary motion into linear motion. It uses ball bearing in a helical groove to transfer the motion with very little friction. The ballscrew mount […]

Make A CNC Milling Machine

Make A CNC Milling Machine I recently decided that I wanted a CNC Milling Machine to add to my workshop. A CNC Milling machine will allow me to do my prototype work in my workshop instead of using a service. Now CNC Milling Machines are not cheap. they can cost tens of thousands of dollars. I am not made of money so I guess a $50,000 CNC Milling Machine is out of the question. But what if I #Make a CNC Milling Machine instead? Could I keep the cost down to a level that won’t break the bank? Can I […]

V Groove Bits

I do a lot of V-Carving with my CNC Signs. I use a V-Groove Bit to do this type of work. One thing I have found is that one of the Best Bist for doing this kind of work is the Laser Point Bit from CMT. Here is a link to the Bit I used. I got it on Amazon (Disclosure). I got this bit after I saw it recommended on one of the CNC Forums I subscribe to. It is one of the best purchases I have made for CNC. Just before Christmas a friend asked me to […]

Motion Control

I recently had a hard drive controller failure on my CNC computer and had to decide to either replace the motherboard or get a new computer. Most new computers don’t have a printer port anymore so it is getting difficult to find a replacement computer. The old CNC computer used a parallel port (printer port) for Motion Control. You either need to purchase a separate Motion Control add-on card for the computer or you had to try to make a USB adapter work. USB converters by themselves don’t work with Mach3. Mach3 needs to be able to control the […]

Edge Lit CNC Sign Project

Recently I made an Edge Lit CNC Sign Project for a school musical. The theater director asked if I could make a lighted sign for the production in a short period of time. The curtain would raise in 3 weeks but the materials couldn’t be purchased for a week and a half. I took on the task and decided to get a head start on the project. I took the artwork the play director provided and began the design work for the sign using Vectric Aspire. I scanned in the image and then created vectors for the artwork. Then I […]