Making a CNC Milling Machine Remove The Head

REMOVE THE HEAD

Well the prep work has been done in my series about making a CNC milling machine. Now it is time to remove the head from the milling column so that I can begin the conversion.

You have to remove the head from the milling machine so that you have access to the mill column. Once the milling column is accessible you can remove it to make a few modifications. By modifying the column you are able to extend the Z axis travel and also install spacers to increase the Y axis travel as well.

TOOLS NEEDED

- Box end wrenches

- Allen Wrenches

- 2 short pieces of 2"x4" or similar

Location, Location, Location.

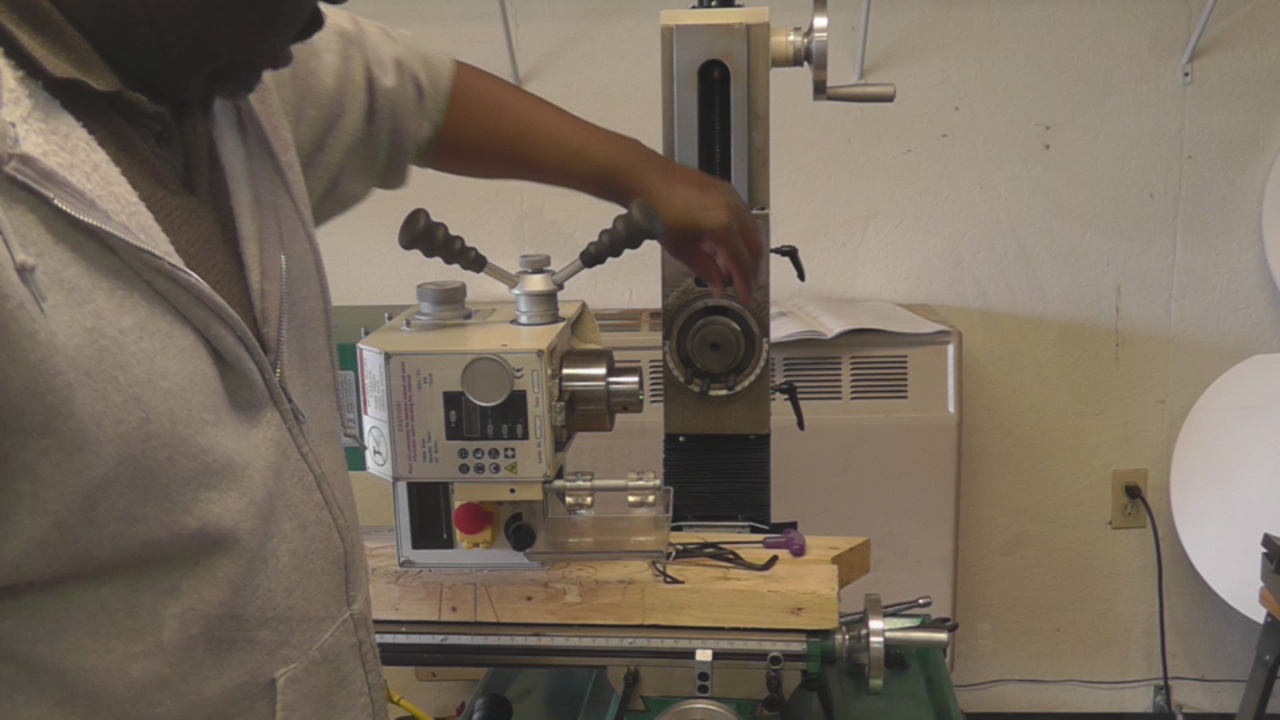

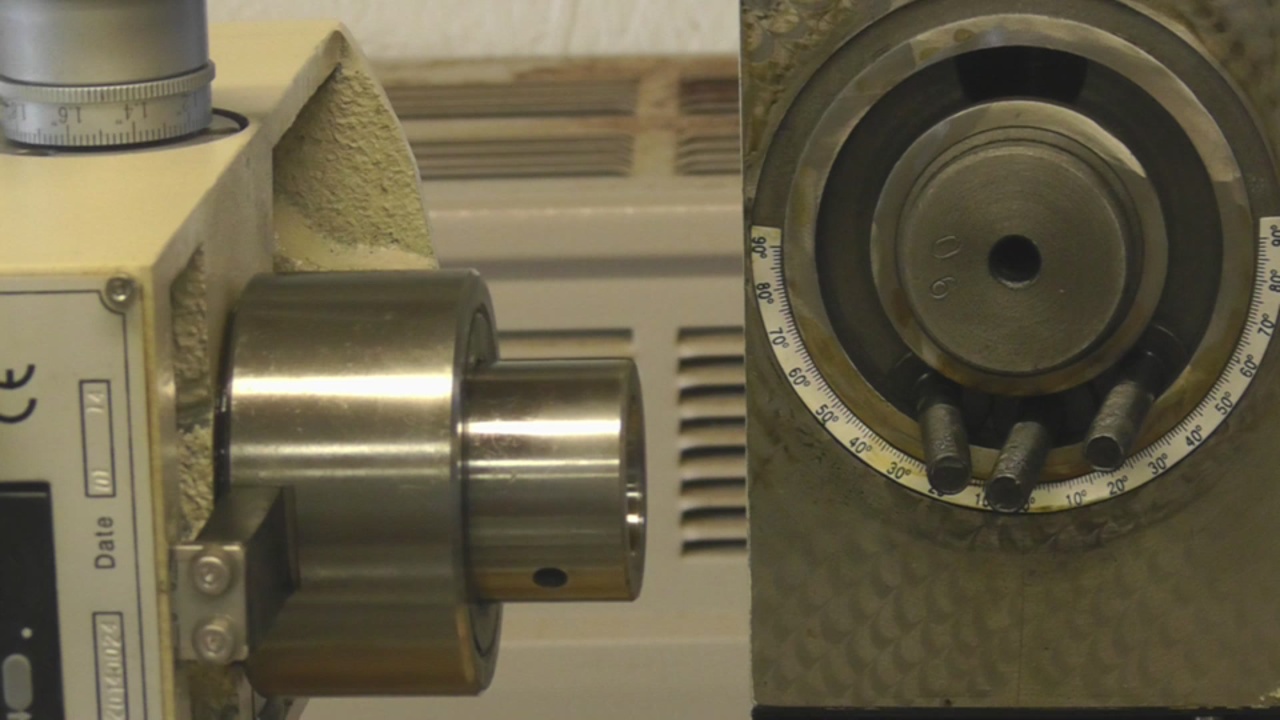

In order to remove the head from the milling column you will have to locate a few setscrews and bolts. On the right side of the mill head (as you are facing the mill) is a hole located between the gibs knobs. This hole contains a setscrew which allows the head to pivot without moving forward. I am telling you about this setscrew now so that you are not fumbling around with it later.

You will also need to locate 4 bolts beneath the head of the mill which holds the head to the column saddle. There is one large center bolt and 3 smaller outer bolts. You will need to loosen all four of these bolts but don't remove them yet. These bolts are not easy to get to and even harder to loosen because the wrench does not have much room. I found that the ratchet box end wrenches made quick work out best for this. I have a set of wrenches that have several sizes on the same wrench and I wish I had more wrenches like this.

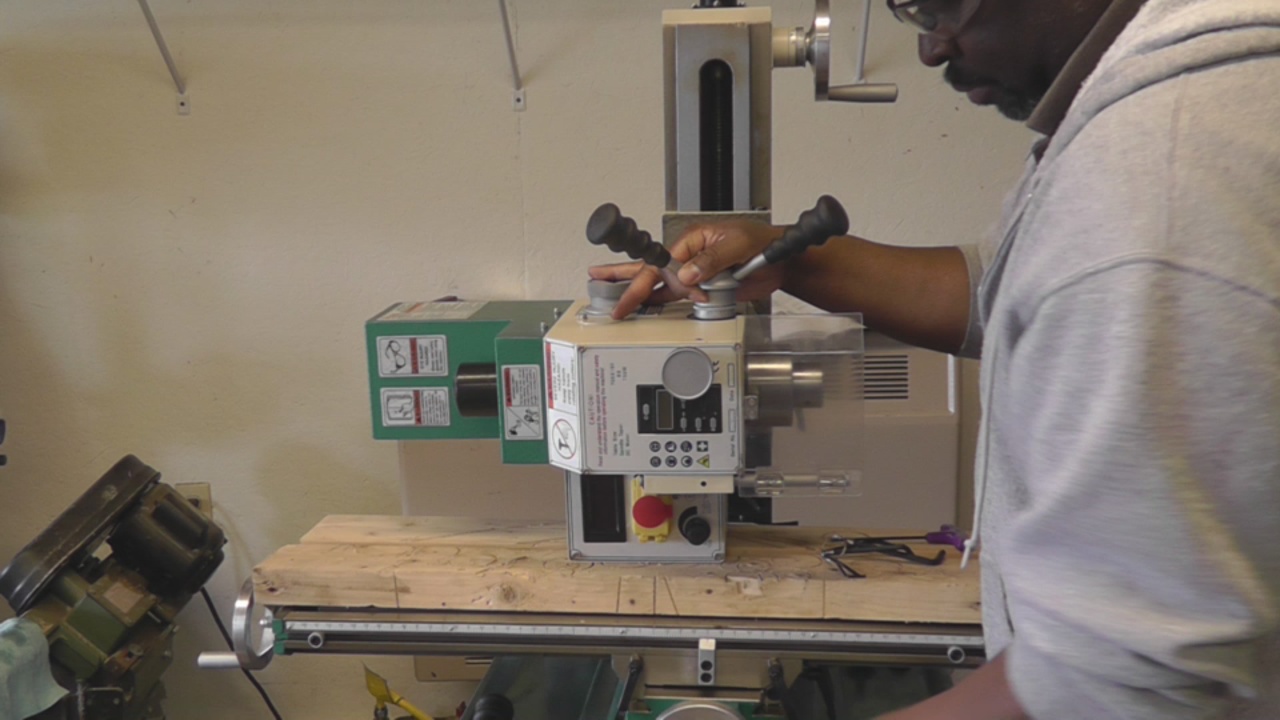

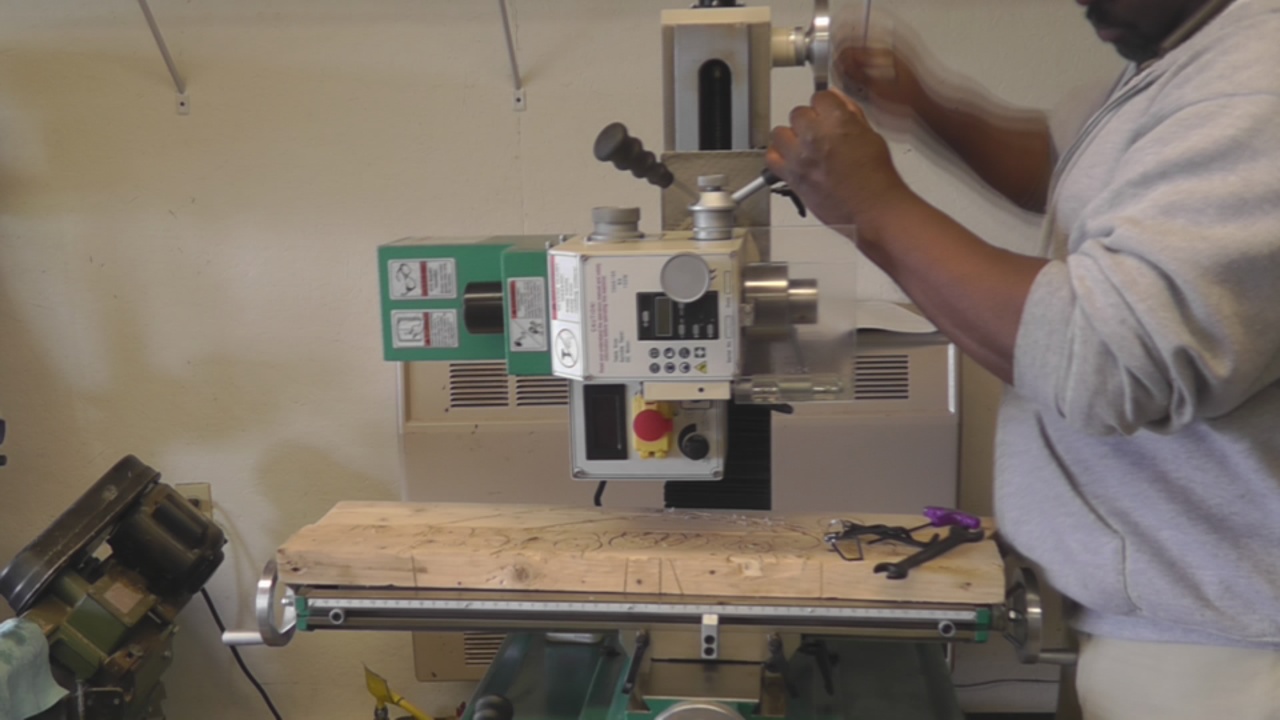

Loosen the 4 bolts and then rotate the head counter clockwise until the control box is parallel to the Milling table. I placed a piece of 2x4 on the milling table to protect it from scratches. Then I lowered the head onto the wood. I removed the bolts from the head.

Next I used the Y axis handle to move the head away from the column and off the bolts that hold it to column. It is much easier to remove the head if you are not supporting the weight with your arm and let the mill table do the work for you.

WATCH OUT!

- Protect the mill table with scrap wood.

- Locate the setscrew on the right side of the head and remove it

- Remove Quill handles if needed.

- Use the mill table to help you remove the head.

Learn how to get accurate cuts with your CNC Router