Faster. CNC. Now.

The software used by More CNC Machines...

Mach4 Features:

Converts a standard PC to a fully featured, 6-axis CNC controller

.

Motion Control at the Core

Synchronous Motion of up to 6 completely separate coordinate systems at the same time.

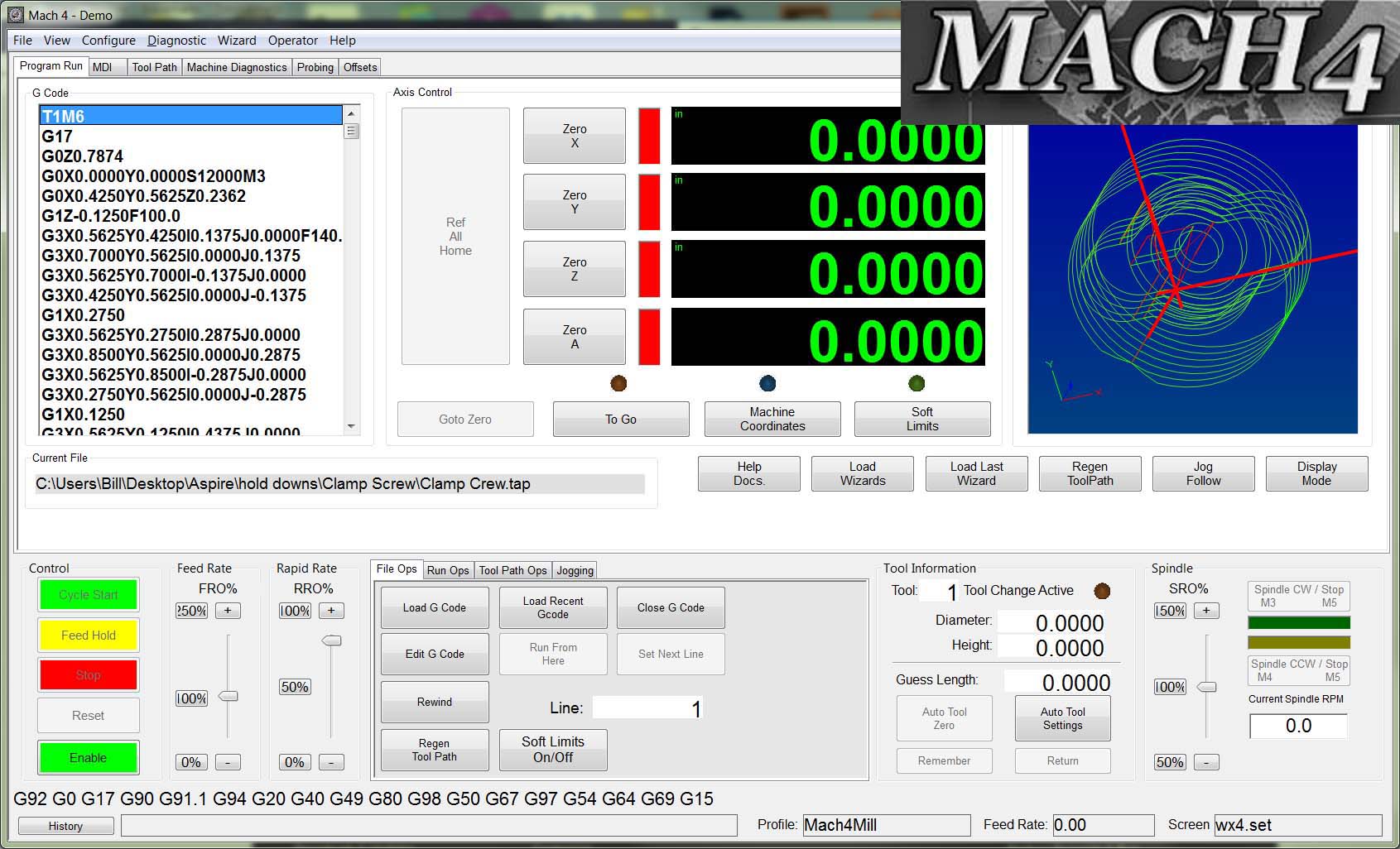

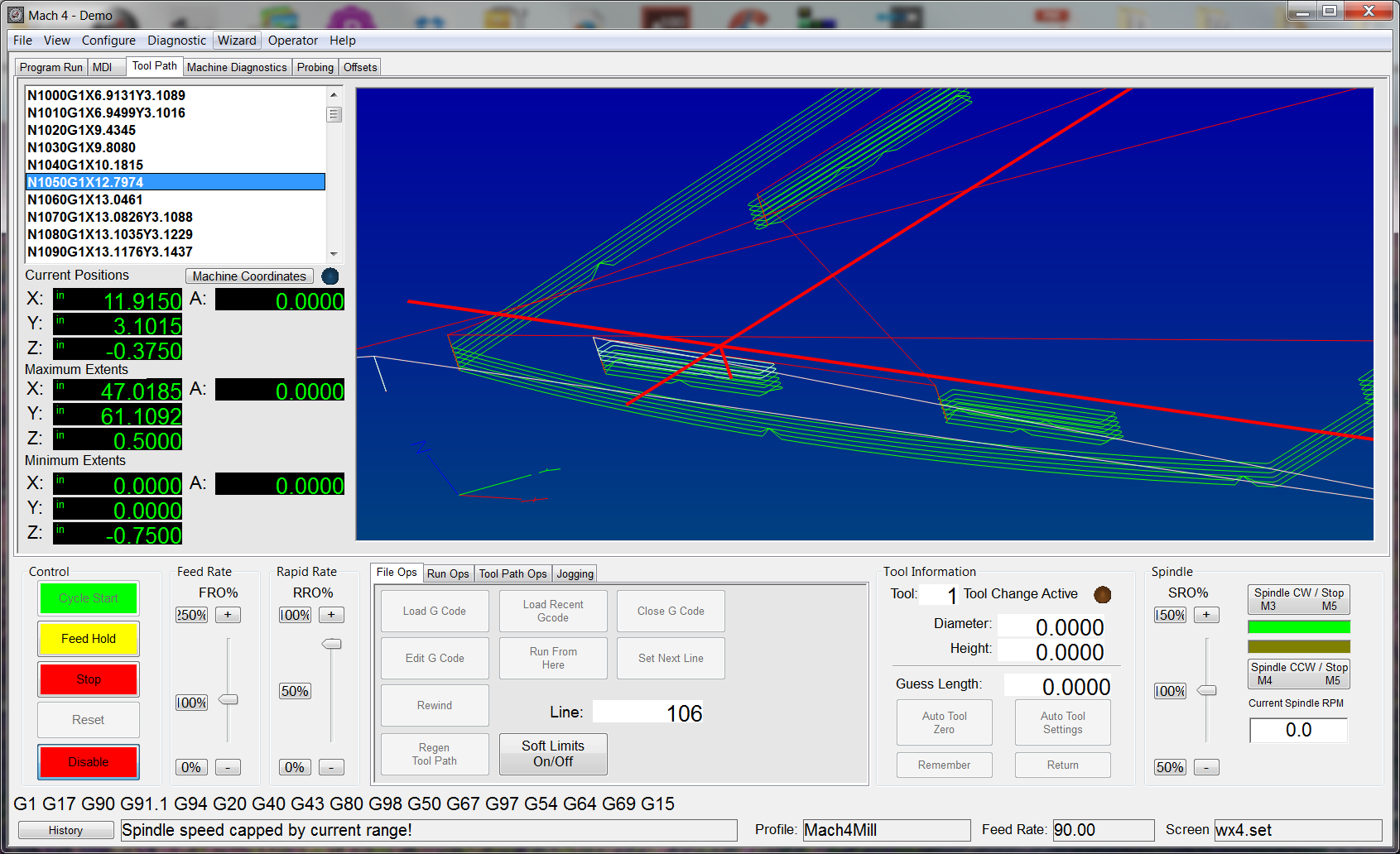

New Dynamic tool path display

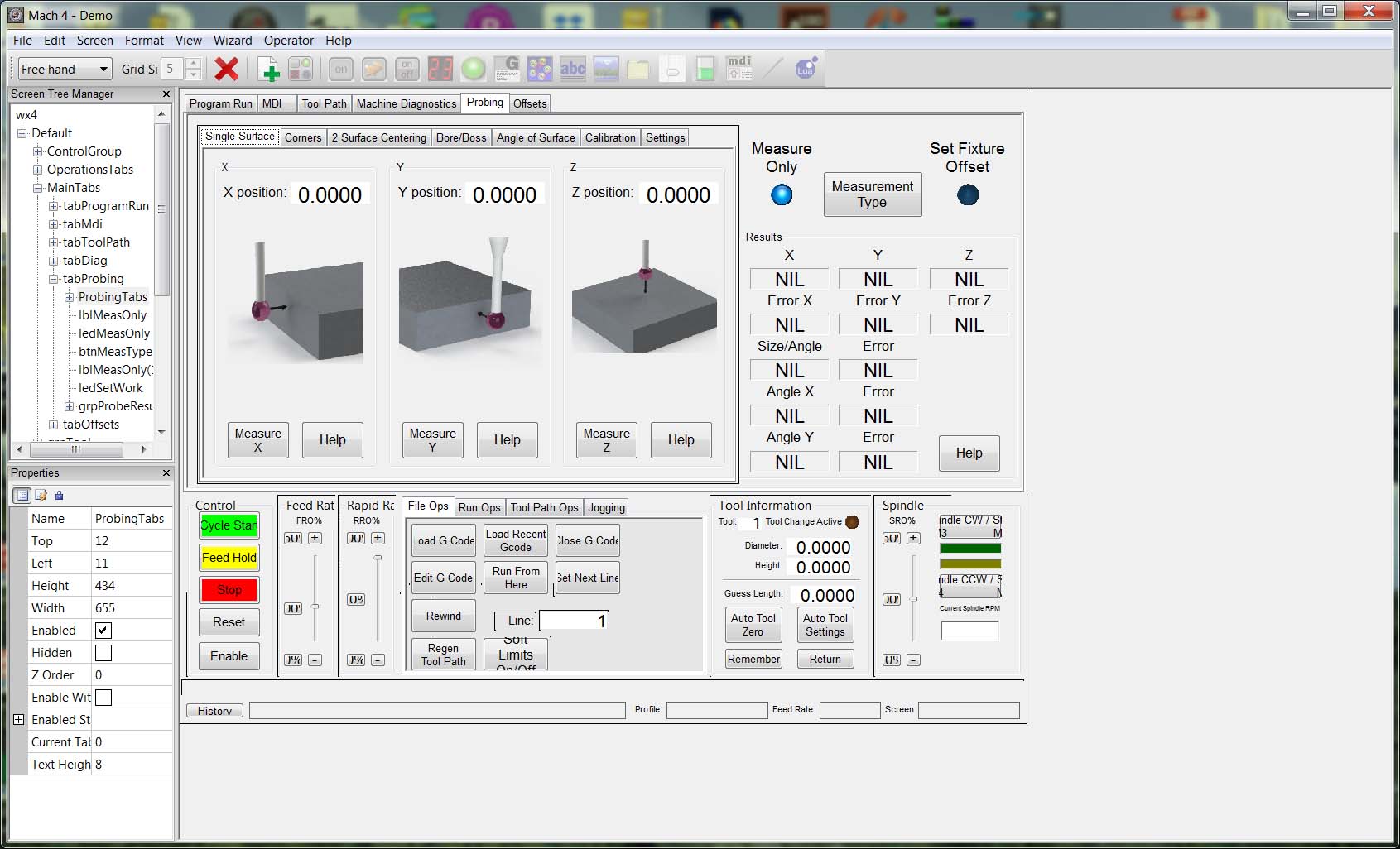

Screen layout and customizable screen modification tools

Don't Wait

Mach4 sale ends on Midnight May 31, 2018.

Get Mach4 NOW

Save $15 Off Regular Price

Why Are So Many Makers Using Mach4?

Mach4 turns a typical computer into a CNC machine controller. Mach4 is completely new software. It was written from the ground up to be expandable, flexible, and extremely responsive for use with very large files. Mach4 was designed for simple hobby machines and still serves this purpose well. When quality, speed, and the ability to use or learn industrial style controls and methods are what is needed, Mach4 is the correct choice. The standard Mach4 installer will control mills, drills, lathes, and routers.

Converts Your PC Into a CNC Controller

Mach4 will convert your PC, into a full featured CNC controller for up to 6 axis. Replace expensive custom hardware with this software solution.

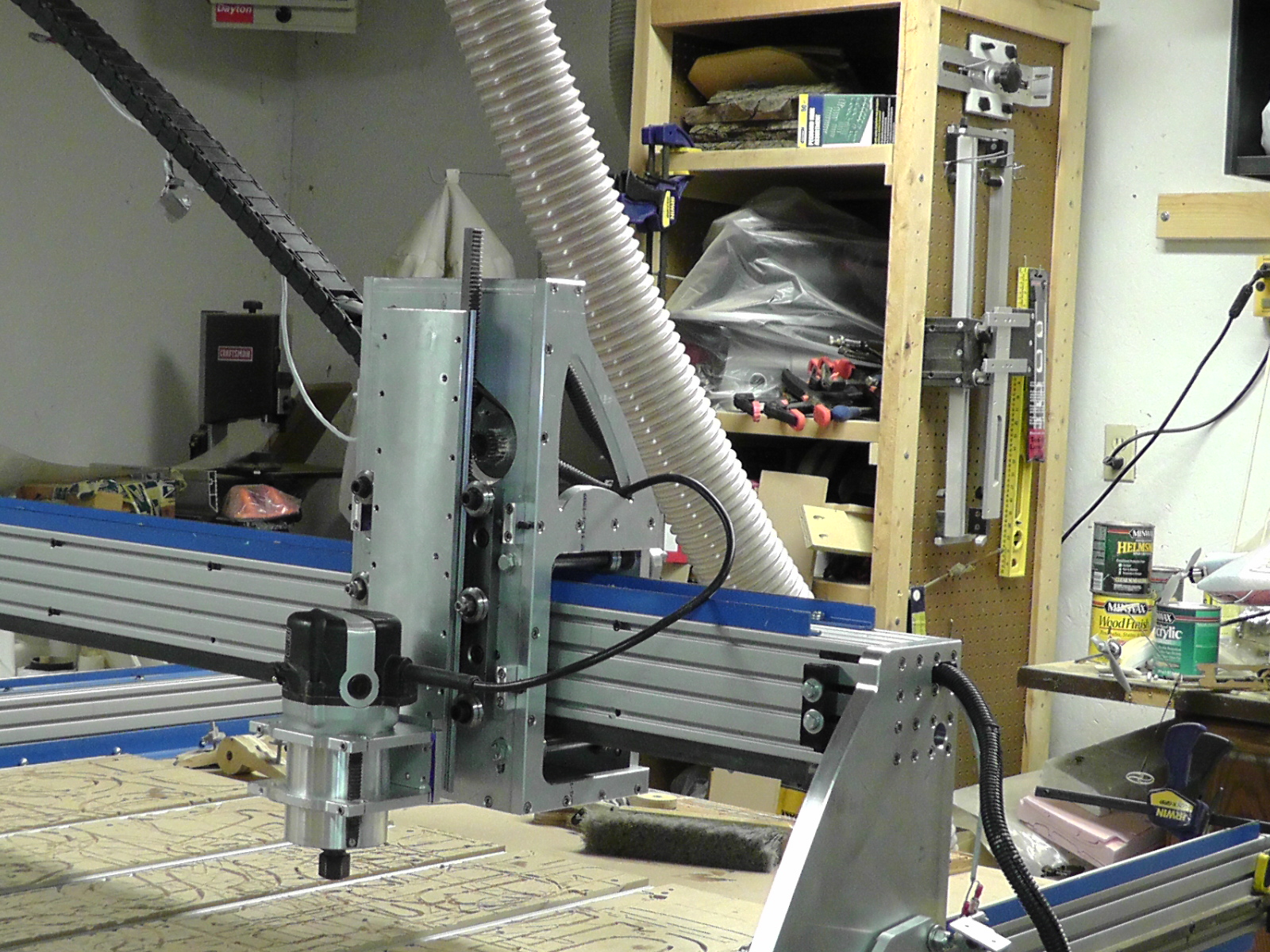

Works with Milling Machines, Lathes & Router Tables

Mach4 has been successfully used to control a variety of machine tools including Milling machines, lathes, routers tables and drills.

Easily Control Peripheral Devices

Mach4 can turn your Spindle On or Off & Control the Speed.Control Multiple Relays, Manual Pulse Generators and works with Touch Screen monitors.

Wizards

Wizards are “mini-programs” that extend the capabilities of Mach4. Wizards can be written by anyone and are designed to allow users to quickly perform routine or convenient operations without the need to have a pre-written G-Code file.

TRY IT BEFORE YOU BUY IT!

Your Purchase Is 100% Protected

Try Mach4 before you buy it and see if it is right for you. Download the free Demo version of the software and try it on your machine. You have nothing to lose and everything to gain. Use my free video tutorials to show you how to set up Mach4 for your CNC Router table and cut an actual project*

All I ask is you try out Mach4 on your machine. Use the demo version of the software to ensure the program is applicable to your needs before you buy it. Take as long as you need.

When you KNOW that Mach4 is the software for you, come back and get a License from me.

Using Mach4

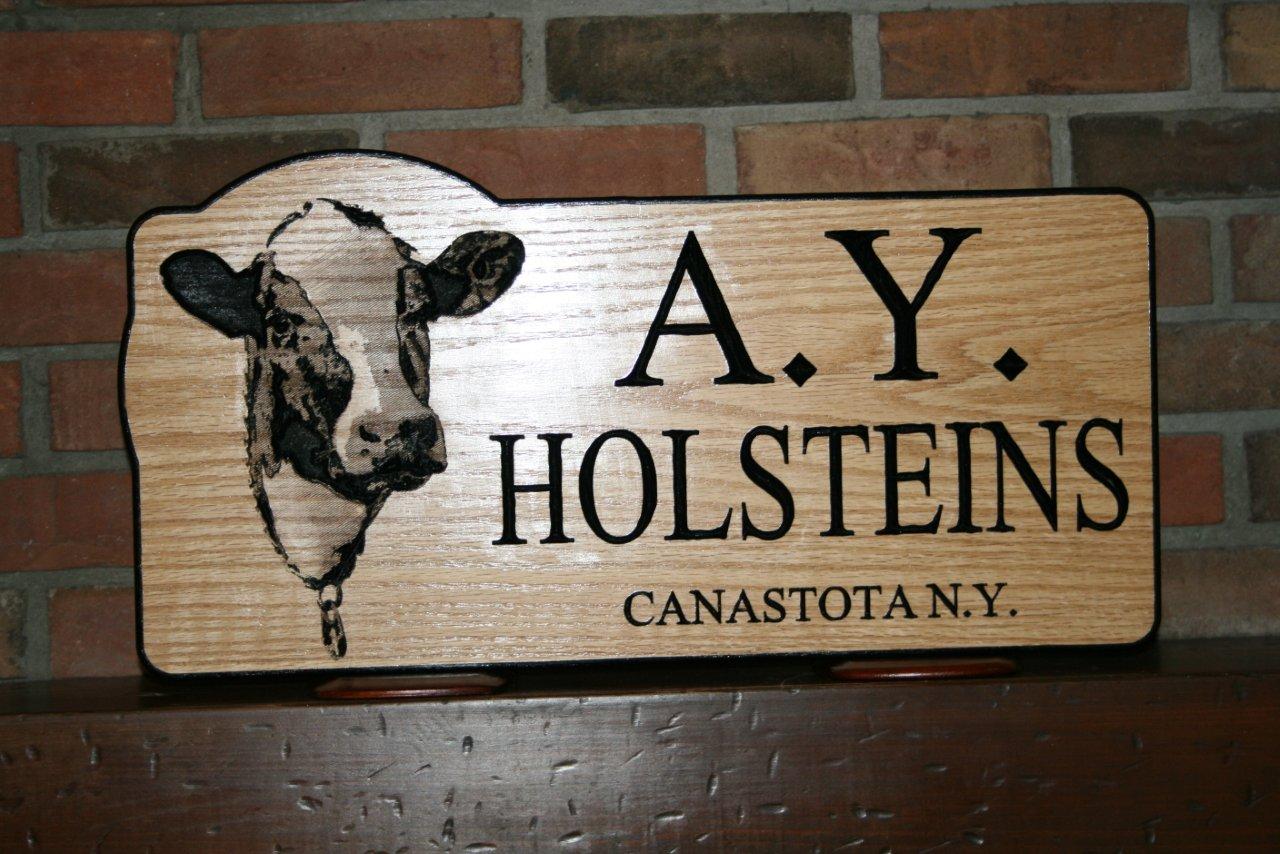

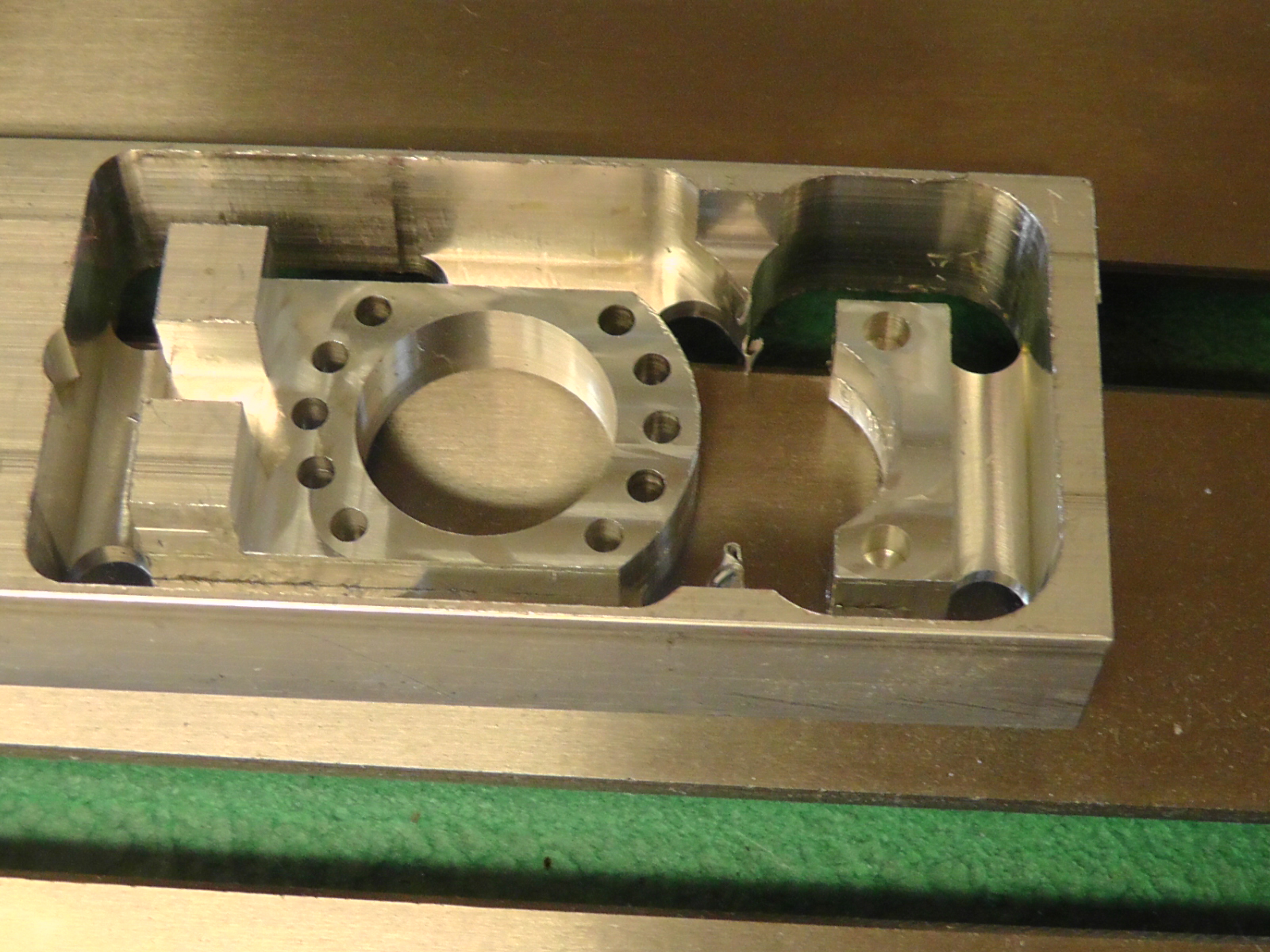

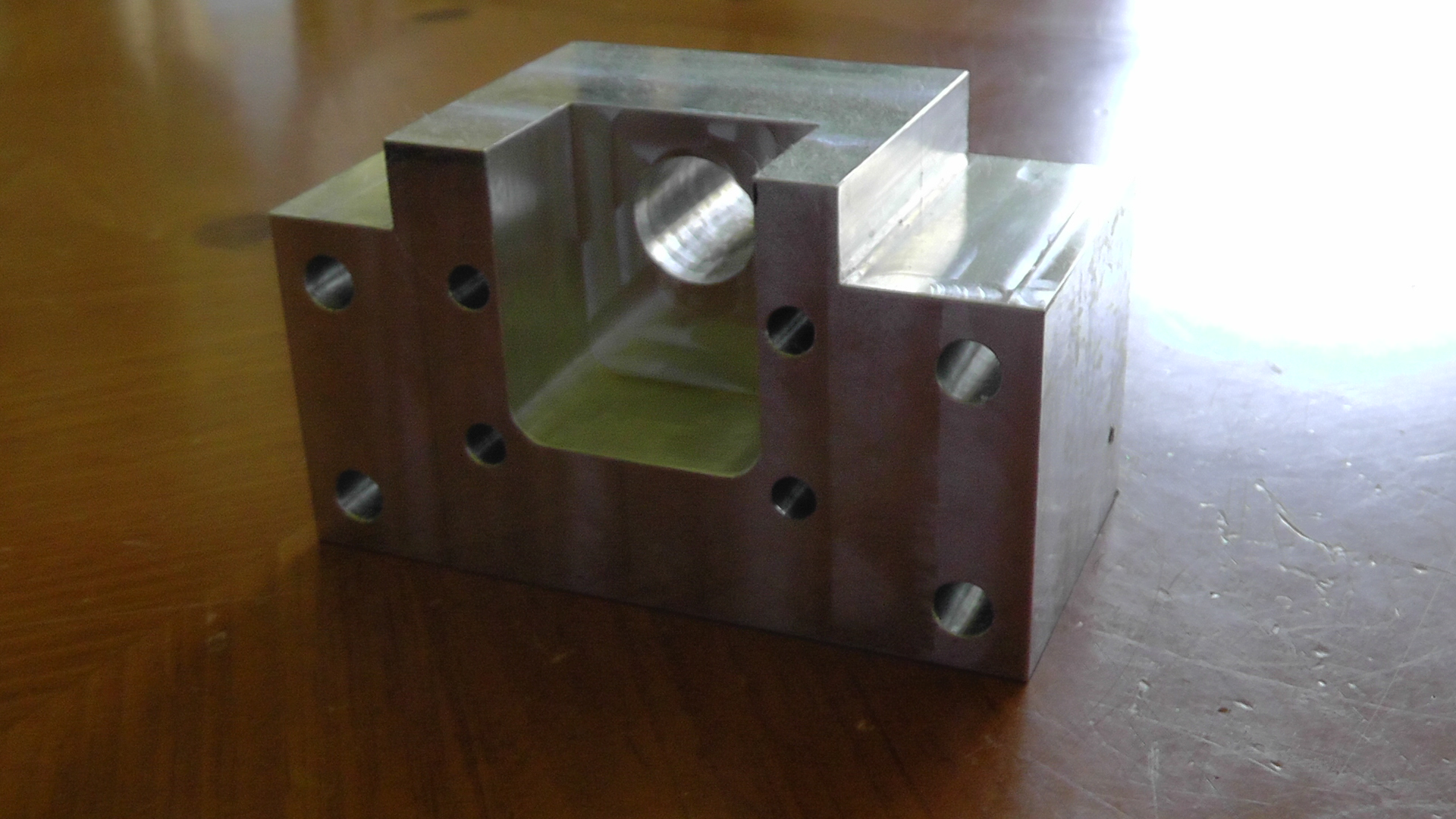

These Projects Were Created...

These Projects Were Created...

Mach4 Has Loads of Powerful Features!

Simulate Tool Path before cutting your parts

See what your G-Code creates before you start cutting. Visually spot errors before you make them.

Zoom in to see details of any part of your design. Rotate the view in 3D to see the project from any angle.

Estimate the run time of your project automatically.

Zoom in to see details of any part of your design. Rotate the view in 3D to see the project from any angle.

Estimate the run time of your project automatically.

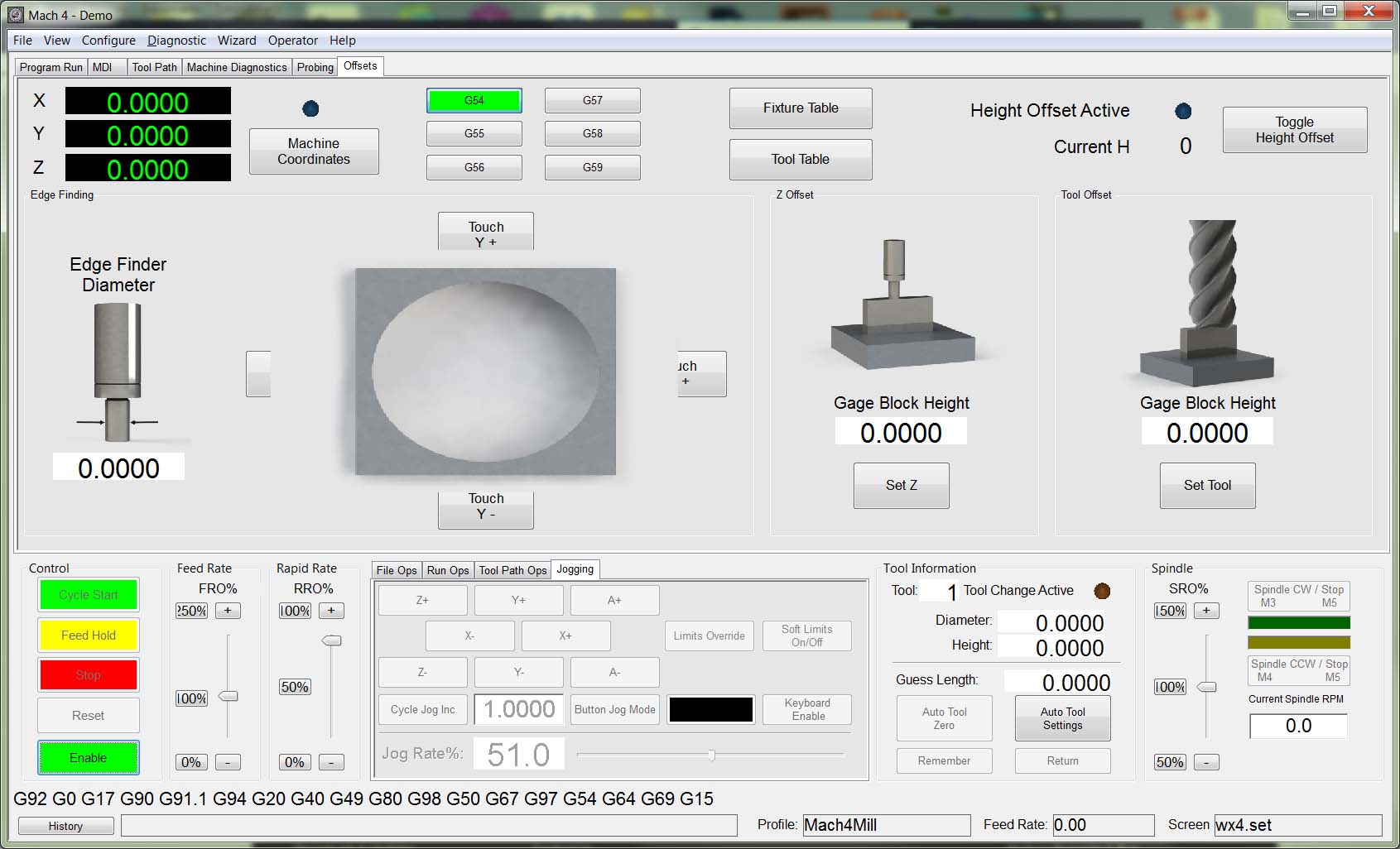

Multiple Work Offsets For Faster Setup

Easily switch between multiple work offsets to accurately machine parts with several tool bits. Use multiple spindles on the same machine.

Use guage blocks or Triple Edge Finder to accurately locate the edge of the work piece.

Use guage blocks or Triple Edge Finder to accurately locate the edge of the work piece.

Create Custom Screen Sets to Make Your Controls Exactly Fit Your Needs

Mach4 screen edit tool allows you to create custom interfaces. You can use the editor on any existing screen or create new ones.

Add new buttons, digital readouts, artwork and menus with a few simple clicks.

Add new buttons, digital readouts, artwork and menus with a few simple clicks.

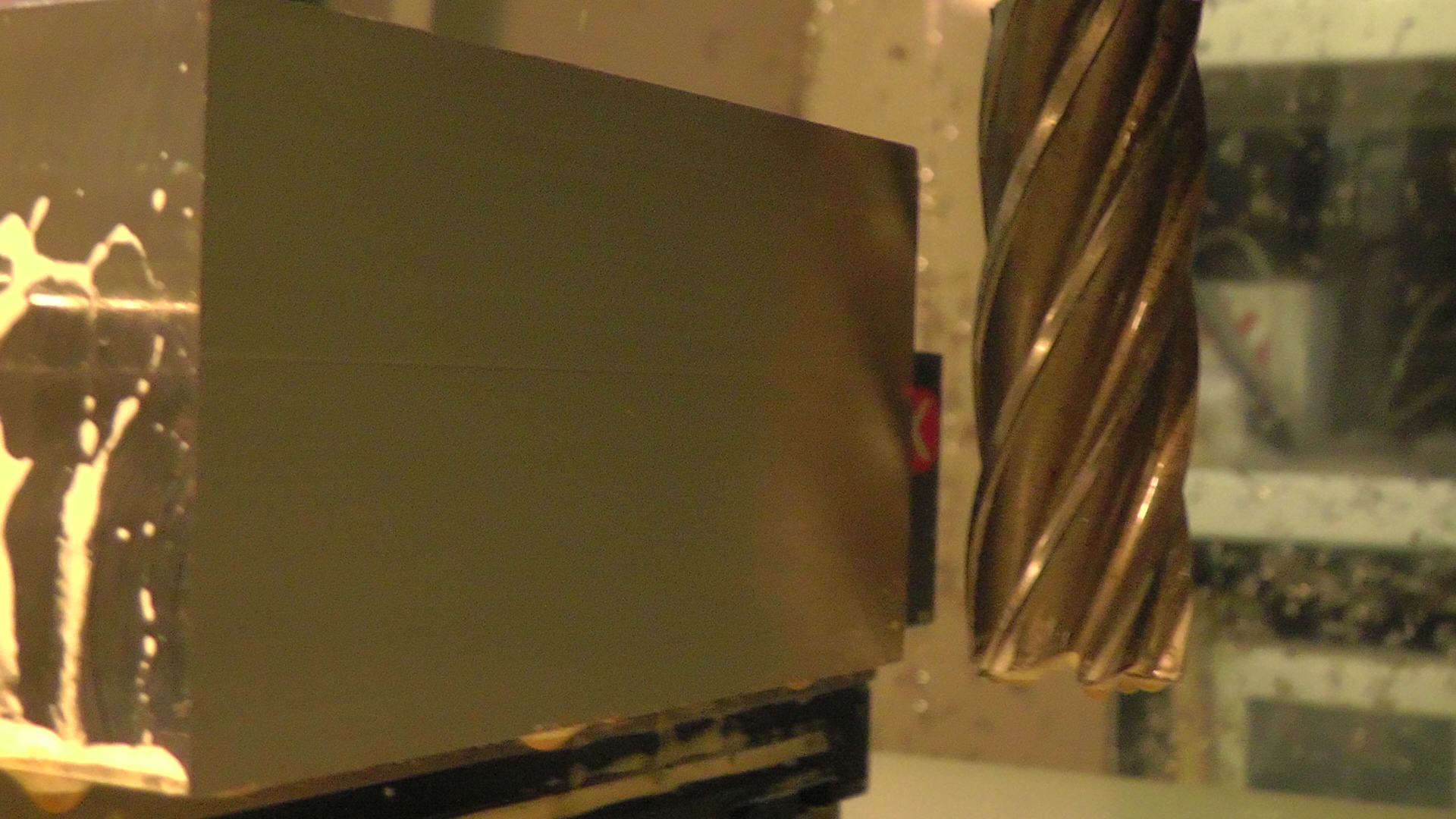

Whether Its Milling

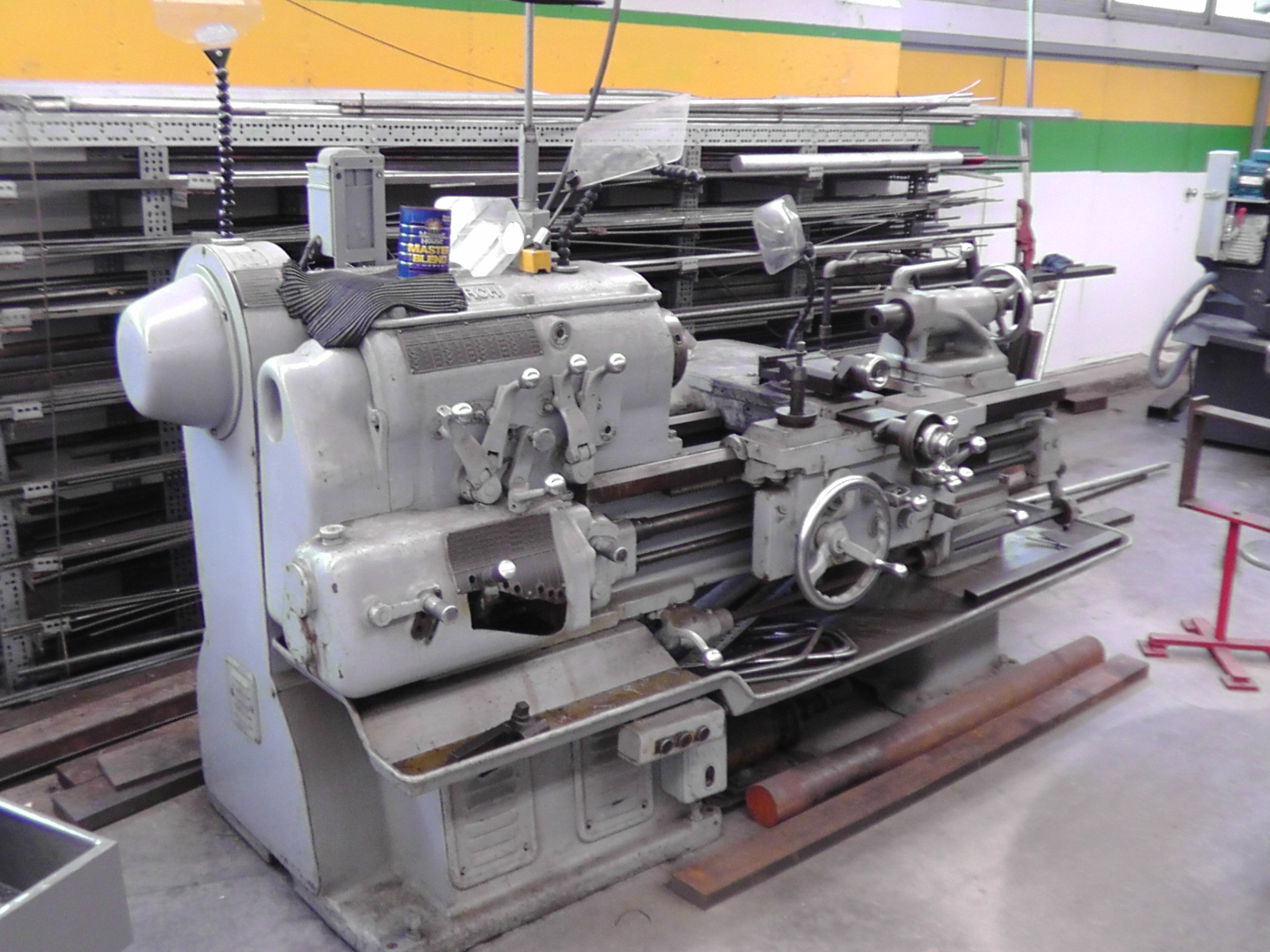

Or Turning

MACH4 GETS WORK DONE!

Get Mach4 Now for $200 Just $185

Secure Your Copy of Mach4 and Take Control of Your CNC Machines…

Frequently Asked Questions & Answers

What Operating System Will Mach4 Run On?

Mach4 Recommended Requirements:

PREFERRED: 32 or 64-bit Laptop or Desktop – Using an External Motion Controller

Windows 10, Windows 8, Windows 7 & Windows XP

An appropriate external motion controller

Mach4 Plugin for the selected Motion Controller

2Ghz CPU

1GB RAM

Video Card with 256MB RAM(Large G-code files, especially 3D files will require a video card with 512MB RAM or higher)

*Use of Parallel Port for machine control only with desktop style computers with 32-bit versions of windows 7 and below.

32-bit Desktop – Parallel Port Recommended Requirements

32-bit version of Windows XP, Windows Vista, or Windows 7

Mach4 Parallel Port Legacy Plugin (cost applicable)

2Ghz CPU

1GB RAM

Non-integrated Video Card with 256MB RAM(Large G-code files, especially 3D files will require a video card with 512MB RAM or higher)

PREFERRED: 32 or 64-bit Laptop or Desktop – Using an External Motion Controller

Windows 10, Windows 8, Windows 7 & Windows XP

An appropriate external motion controller

Mach4 Plugin for the selected Motion Controller

2Ghz CPU

1GB RAM

Video Card with 256MB RAM(Large G-code files, especially 3D files will require a video card with 512MB RAM or higher)

*Use of Parallel Port for machine control only with desktop style computers with 32-bit versions of windows 7 and below.

32-bit Desktop – Parallel Port Recommended Requirements

32-bit version of Windows XP, Windows Vista, or Windows 7

Mach4 Parallel Port Legacy Plugin (cost applicable)

2Ghz CPU

1GB RAM

Non-integrated Video Card with 256MB RAM(Large G-code files, especially 3D files will require a video card with 512MB RAM or higher)

What is a Plugin?

A plugin (or plug-in) allows people to add custom functionality to Mach4.

Mach4’s modular design allows features to be added and removed without affecting the systems operation. This aspect greatly enhances the flexibility for different applications, machines and uses.

– Different modules of the core can be removed, added, or created to create a custom software package for OEM’s, re-sellers, and educational organizations.

– Everything is customizable, Make the software your Own

Create Proprietary add-ons for your version

Custom Installers

Rapid Application Development (RAD) with our Screen Design Mode

Increase or decrease functionality with Plug Ins and Add-ons

Customizable M Codes for Machine Specific Functions

– No fixed amount of IO

IO registered to system without any software interference between devices.

Mach4’s modular design allows features to be added and removed without affecting the systems operation. This aspect greatly enhances the flexibility for different applications, machines and uses.

– Different modules of the core can be removed, added, or created to create a custom software package for OEM’s, re-sellers, and educational organizations.

– Everything is customizable, Make the software your Own

Create Proprietary add-ons for your version

Custom Installers

Rapid Application Development (RAD) with our Screen Design Mode

Increase or decrease functionality with Plug Ins and Add-ons

Customizable M Codes for Machine Specific Functions

– No fixed amount of IO

IO registered to system without any software interference between devices.

How do I cut My Drawing? Can I Load it Directly Into Mach4?

Transforming an idea into an actual part is a 3-step process: CAD –> CAM –> Control. Mach4 is the Control part of the process and requires G-code files produced by a CAM or Wizard program.

Wizard programs are the most simple for those new to CNC.

Advanced users/machinist will often write their own G-code.

Wizard programs are the most simple for those new to CNC.

Advanced users/machinist will often write their own G-code.

What is CAD?

Computer-aided design (CAD), computer-aided drafting (CAD), or computer-aided design and drafting (CADD) is the process of using a computer to design and draw the parts you would like to create. The CAD files then need to go through a CAM process to become the G-code files that Mach3/Mach4 uses.

What Is G-Code?

Used mainly in automation, G-code is the common name for the most widely used numerical control (NC) programming language, which has many implementations. G-code is sometimes called G programming language.

What Is CAM?

Computer-aided manufacturing (CAM) is a subsequent process after CAD. The CAD files are loaded into the CAM program, the desired machining parameters (tools, cut depths, etc) are chosen, and toolpaths (in the form of a gcode file) are created which then control the machine tool. The G-code files are formatted based on the postprocessor chosen.

Copyright 2018 - The Makers Guide - All Rights Reserved